The material classification of cable bridge is described briefly

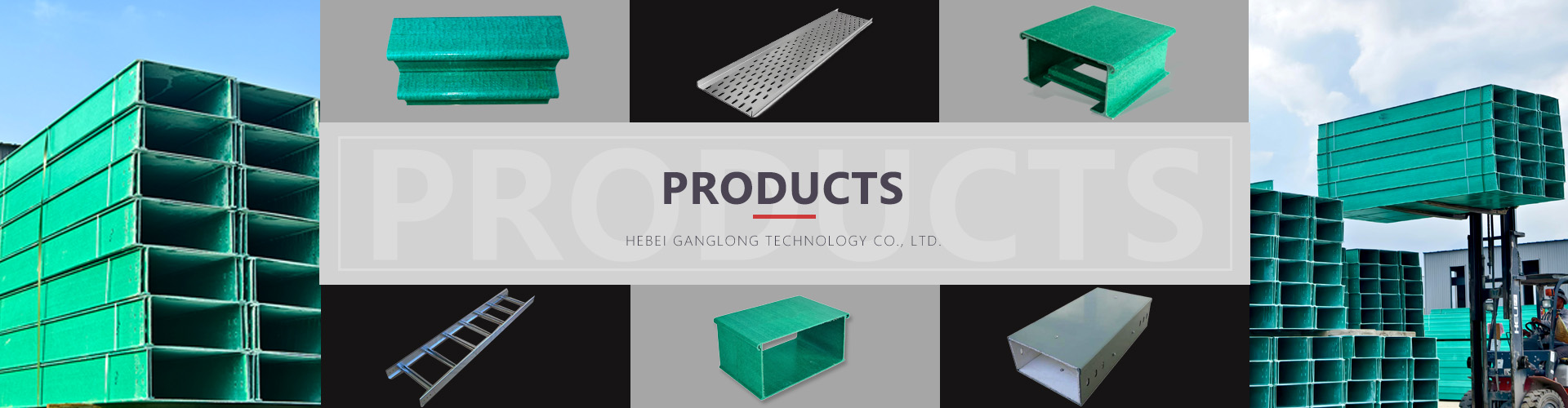

1. Glass fiber reinforced plastic bridge has the stiffness of metal bridge and the toughness of glass fiber reinforced plastic bridge, good corrosion resistance and strong aging resistance. It can be widely used in petroleum, chemical, electric power, light industry, television, communication and other industries.

2. Stainless steel: The raw materials of stainless steel cable bridge are made of stainless steel plates of different types and materials. In general, the surface does not require treatment. The strength and corrosion resistance of pallets are much higher than that of ordinary pallets.

3. Aluminum alloy: Aluminum alloy cable tray has simple structure, novel style, heavy bearing, light weight, corrosion resistance, long service life and easy installation. It is suitable for general environmental areas, coastal foggy areas, high humidity and high wind areas. In corrosive environment, the unique anti-corrosion properties of aluminum alloy cable bridge can be brought into play.

4, hot galvanizing: hot galvanizing is a very good. This plating method not only has the corrosion resistance of electrogalvanizing, but also has a zinc-iron alloy layer. It also has a strong corrosion resistance unmatched by electric galvanizing. Therefore, this plating method is especially suitable for a variety of strong acid, alkali fog and other strong corrosive environment.

5. Fireproof spraying: Spraying cable bridge is a surface treatment method for spraying plastic powder on cable bridge. It is more suitable for laying and installing in fire passages, pipelines and other places.

6, steel plate: steel plate cable bridge is a common cable bridge, and various processes can be carried out on its surface to achieve different performance characteristics.