Cable trays are an essential component of modern infrastructure, used to support and manage electrical cables and wiring in a variety of buildings and industrial settings. One critical aspect of cable tray production is determining the weight per meter of the trays. This factor is crucial for ensuring that the trays can effectively support the load of the cables they will contain, while also being cost-effective to manufacture and transport.

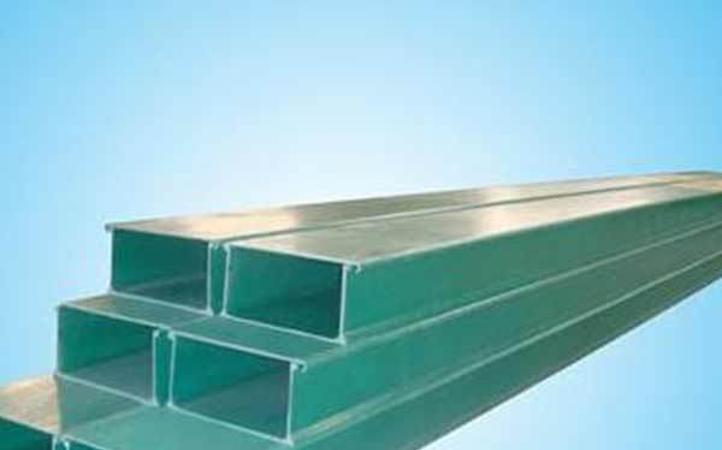

In production technology, the weight per meter of a cable tray is influenced by several factors. The material used in construction is a significant determinant of the weight, with options including steel, aluminum, and fiberglass. Each material has its strengths and weaknesses, and the choice depends on the specific requirements of the project. For example, steel cable trays are known for their durability and strength, but they are also heavier than aluminum or fiberglass options. Conversely, aluminum trays are lighter and more resistant to corrosion, making them suitable for outdoor and corrosive environments.

Another key factor in determining the weight per meter of a cable tray is the design and construction of the tray itself. The shape, size, and structure of the tray all contribute to its overall weight. For example, a solid-bottom cable tray will naturally weigh more than a wire-mesh tray due to the additional material used. Additionally, the spacing and arrangement of the support rungs will affect the weight distribution and load-bearing capacity of the tray. Production technology plays a critical role in optimizing these design parameters to achieve the desired weight per meter while maintaining structural integrity.

Once the material and design parameters are established, production technology is used to manufacture the cable tray to meet the specified weight per meter. This process involves precision cutting, forming, welding, and finishing to create trays of consistent dimensions and weight. Advanced manufacturing techniques, such as laser cutting and robotic welding, are often employed to ensure accuracy and efficiency in production. Quality control measures are also implemented to verify that the final products meet the weight specifications and performance standards.

In conclusion, the weight per meter of a cable tray is a crucial consideration in production technology, as it directly impacts the performance, cost, and logistics of the trays. Through careful material selection, design optimization, and precision manufacturing, cable tray manufacturers can achieve the desired weight per meter while meeting the structural and functional requirements of their customers. As technology continues to advance, the production of cable trays will likely become even more efficient and customizable, further enhancing their utility in various applications.

need a quote? GangLong product manager always welcome you to call back.