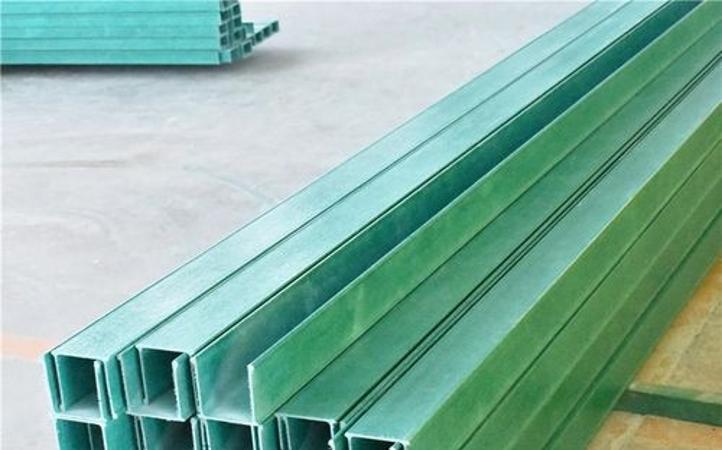

Electrical insulating fiberglass epoxy laminates are highly regarded for their exceptional insulating properties and mechanical strength, making them a fundamental material in the electrical and electronics industry. Their production process is a blend of precision engineering and advanced technology, ensuring optimal performance and reliability.

To begin with, the production of fiberglass epoxy laminates involves the impregnation of fiberglass cloth with an epoxy resin. This resin acts as a binder, ensuring that the fiberglass is adequately held together and also providing excellent insulating properties. The impregnation process requires accurate control of resin viscosity and curing parameters to ensure consistent quality of the laminate. Advanced technologies such as computer-controlled impregnation lines have been developed to automate and monitor this process, thereby increasing the efficiency and reducing material wastage.

Once the fiberglass cloth has been impregnated with epoxy resin, it undergoes a lamination process. The lamination process involves stacking multiple layers of impregnated fiberglass cloth, which are then subjected to pressure and heat in a hydraulic press. This stage is crucial as it determines the uniformity, density, and overall mechanical strength of the laminate. Cutting-edge hydraulic presses equipped with sophisticated temperature and pressure control systems are utilized to ensure a consistent and repeatable lamination process.

After lamination, the fiberglass epoxy laminate needs to be cured. The curing process involves maintaining the laminate under controlled temperature and pressure conditions for a specified duration. This ensures the complete polymerization of the epoxy resin, thereby imparting dimensional stability and rigidity to the laminate. Innovations in curing technologies have facilitated more energy-efficient and accelerated curing processes, which have significantly improved the throughput and quality of the final product.

Lastly, quality control and testing play a pivotal role in the production of electrical insulating fiberglass epoxy laminates. Rigorous testing protocols are established to evaluate the electrical, mechanical, and thermal properties of the laminates. These tests not only comply with international safety and performance standards but also help to identify any discrepancies early in the production process. Advanced testing equipment, automated defect detection systems, and data analytics tools have greatly enhanced the accuracy and reliability of quality control processes.

In conclusion, the production technology for electrical insulating fiberglass epoxy laminates continually evolves, incorporating more automation and precision control to meet the growing demands of the electrical and electronics industry. By leveraging state-of-the-art equipment and innovative production techniques, manufacturers ensure that these laminates provide robust and reliable insulation in various applications.

need a quote? GangLong product manager always welcome you to call back.